Introduction: Why Mass Matters

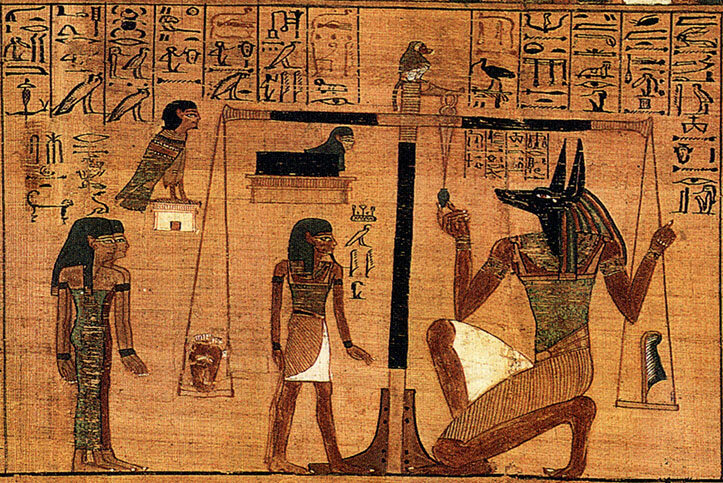

Mass was one of the first quantities humans attempted to measure and standardize — shaping trade, science, and trust.

From grains weighed in clay bowls to high-precision digital balances used in pharmaceutical labs today, the measurement of mass has always held a central role in human civilization. Long before electrical circuits and digital sensors, ancient merchants and scholars recognized the need to quantify the weight of goods and materials — not only to facilitate fair trade, but also to ensure consistency, safety, and reproducibility in processes.

Mass was among the first quantities that people attempted to standardize. Its importance shaped the earliest systems of commerce, agricultural exchange, and scientific experimentation. In fact, some of the earliest records of measurement come from Mesopotamian clay tablets detailing units for silver, grain, and other commodities. These primitive systems would lay the foundation for increasingly sophisticated methods — from balancing levers with stone weights to the emergence of analytical balances capable of resolving mass down to the microgram.

Understanding how mass measurement evolved isn’t just a historical exercise. It helps contextualize the tools we rely on today — tools designed to deliver accuracy in the face of ever-more demanding standards in chemistry, biology, medicine, and materials science.

Key Features:

- ⚖️ Single-arm Lever Balances and External Weights

Before the age of electronics and digital displays, mass was measured using simple mechanical systems rooted in physics — one of the earliest and most influential designs being the single-arm lever balance.

🪙 How It Worked

These balances used a horizontal beam (lever) suspended at a central pivot point. On one side, an object of unknown mass was placed; on the other, standardized external weights were added until equilibrium was achieved. When the beam balanced horizontally, the total mass of the known weights equaled that of the unknown object.

This type of scale wasn’t just intuitive — it was universal. From Egyptian markets to medieval apothecaries, merchants and scholars relied on the same principle: balance equals truth.

External Weights – The first standards

External weights were crafted from metal or stone and came in fixed denominations. These units evolved into standardized systems that laid the groundwork for formal metrology. Over time, various civilizations developed their own sets of reference weights — some inscribed with symbols, others shaped to prevent tampering.

Using external weights also allowed flexibility: the same balance could be used to measure anything from grain to gold simply by choosing the appropriate counterweights.

🌍 Global Impact

What started as a basic lever and some weights became a global symbol of fairness and precision. The concept survives today in modern analytical balances, even as technology has replaced metal beams with sensors and microprocessors.

⚙️ Unequal-arm Balances and Mechanical Innovation

As civilizations grew more sophisticated, so did their tools for measuring mass. While the equal-arm balance offered simplicity, its design had limitations — especially in terms of scale size and portability. This led to the development of unequal-arm balances, which introduced new mechanical principles and ushered in an era of innovation in weighing technology.

🔧 What Is an Unequal-arm Balance?

Unlike the symmetrical beam of equal-arm designs, the unequal-arm balance features two arms of different lengths. The shorter arm typically carries a pan or hook for the load, while the longer arm holds a sliding counterweight or fixed standard mass. Instead of directly comparing two masses, the mechanism uses leverage — meaning the position of the weight along the beam affects the reading.

This design was revolutionary because it allowed:

- Faster measurements without adding multiple external weights

- Compact construction for field and industrial use

- Greater sensitivity in small ranges of mass

🏭 Early Manufacturers and Mechanical Ingenuity

With the rise of industrialization, manufacturers began refining these balances into precise instruments. Companies in Germany, France, England, and later the United States pioneered metal alloys, enclosed pivots, and adjustable fulcrums to reduce friction and improve repeatability.

Some of the earliest models even included mechanical dial indicators — a precursor to modern digital displays — that translated weight shifts into legible readings without requiring interpretation from counterweights or beam deflection.

📐 Standardization Begins

As these instruments became more reliable, governments and metrology institutes began promoting uniform weight standards, and calibrating balances became an essential process. This shift laid the foundation for organizations like OIML and the formal introduction of accuracy classes.. ⚖️🔬

🔬 The Rise of Analytical and Precision Balances

The growing demands of scientific research required tools capable of measuring mass with extraordinary sensitivity. Enter analytical balances and precision balances — engineered to quantify materials down to the milligram, microgram, or even nanogram scale.

🧪 Analytical Balances

These instruments are built for extremely fine measurements, often with readability of 0.0001 g (0.1 mg) or better. They feature enclosed weighing chambers to shield the sample from air currents, vibration, and temperature fluctuations — all of which can affect results at such high resolution.

Modern analytical balances rely on electromagnetic force restoration (EMFR). Instead of measuring weight directly, the system detects the displacement caused by the sample and then restores balance using a precisely controlled counter-force. The strength of this restoring force is converted into a digital readout.

Applications include:

- Pharmaceutical formulation

- Chemical reagent preparation

- Micro-sample analysis in biology and material science

⚖️ Precision Balances

Precision balances offer readability between 0.01 g to 0.001 g, making them ideal for tasks that don’t require full micro-level sensitivity but still demand reliable results. They often support higher capacity ranges and are used in quality control labs, educational settings, and field environments.

Key distinctions:

- Analytical balances: Higher resolution, lower capacity, enclosed chamber

- Precision balances: Lower resolution, higher capacity, open design

Together, these two categories bridge the gap between exact science and practical application. They empower researchers to validate hypotheses, formulate compounds, and maintain traceability across industries that rely on mass measurements.

📏 OIML Standards and Accuracy Classes

As laboratory instruments became increasingly precise, the need for international standards emerged. Without a universal system of calibration, measurements could vary wildly between labs, countries, and industries. This is where the International Organization of Legal Metrology (OIML) stepped in — establishing guidelines that remain foundational in scientific measurement today.

🌐 What Is OIML?

Founded in 1955, the OIML creates frameworks for the uniform manufacture, calibration, and use of measuring instruments, including balances and weights. Its standards are recognized by national metrology institutes and legal authorities around the world, ensuring that devices meet specified performance criteria.

These standards classify balances and weights into distinct accuracy classes, each with defined tolerances and intended applications.

⚖️ Accuracy Classes for Balances

- Class I (Special accuracy):

Readability from 0.001 g to 0.000001 g

Used in high-precision analytical laboratories and pharmaceutical R&D - Class II (High accuracy):

Readability from 0.1 g to 0.001 g

Common in quality control, academic labs, and medical diagnostics - Class III (Medium accuracy):

Readability from 1 g to 0.1 g

Used in industrial, agricultural, and commercial settings

Each class ensures that the balance not only measures correctly but maintains stability, repeatability, and resistance to environmental noise. When paired with OIML-certified weights, these instruments become part of a traceable system of measurement — one that regulators, researchers, and manufacturers can rely on.

🧠 Why It Matters

Working within accuracy classes helps labs:

- Comply with international quality standards (e.g., ISO, GLP, GMP)

- Ensure consistency across experiments and manufacturing runs

- Maintain legal integrity in regulated industries like pharma and food safety

Knowing which class your balance belongs to — and how it’s calibrated — isn’t just technical trivia. It’s essential knowledge for making confident decisions in the lab.

❓ Frequently Asked Questions (FAQ)

What is the difference between analytical and precision balances?

Analytical balances offer higher readability (typically 0.0001 g or better) and are enclosed to protect measurements from air currents. Precision balances have lower readability (0.01–0.001 g) and usually offer higher capacity for less sensitive applications.

Why were external weights important in early mass measurement?

External weights provided standardized references for balancing scales. They allowed users to compare unknown masses by achieving equilibrium against known quantities — a system that underpinned early trade and legal measurement.

What does OIML stand for?

OIML is the International Organization of Legal Metrology. It sets global standards for the design, calibration, and accuracy of measuring instruments, including balances and weights.

Which OIML class is suitable for my laboratory?

– Class I: For high-end analytical research- Class II: For general laboratory use and diagnostics- Class III: For industrial, agricultural, or educational useThe choice depends on required accuracy, sample size, and regulatory context.

How are modern balances calibrated?

Most modern lab balances are calibrated using certified weights that conform to OIML standards. Many analytical models also feature internal motorized calibration systems, ensuring consistency between uses.

Measurement – First Step in Laboratory Work

Understanding accuracy, calibration, and the science behind laboratory instruments.

Why Measurement Matters

Measurement is the foundation of laboratory science. From mass and volume to pH and color,

every reliable result begins with a well-calibrated instrument. Among all quantities,

mass was one of the first that humans attempted to measure and standardize — shaping trade, science, and trust across civilizations.

To explore the evolution of mass measurement, visit our article:

From Ancient Balances to Analytical Precision

Understanding Accuracy vs. Precision

- Accuracy refers to how close a measurement is to the true value.

Example: hitting the bullseye on a target. - Precision describes how consistent repeated measurements are.

Example: clustering shots tightly together, even if off-center.

Calibration: The Science of Precision

Regular calibration ensures that instruments remain accurate and precise over time.

Environmental factors, wear, and drift can affect readings — calibration corrects these deviations.

- ✅ Ensures true values

- ✅ Improves consistency

- ✅ Maintains compliance (ISO 17025, CE)

Common Calibration Methods

| Instrument Type | Calibration Method |

|---|---|

| Balances & Scales | Certified weights (OIML Class E1–F2) |

| Spectrophotometers | Standard light sources |

| pH Meters | Buffer solutions (pH 4.00, 7.00, 10.00) |

| Colorimeters | Reference tiles or solution standards |

How Often Should Calibration Be Done?

- Daily or Before Use: pH meters, balances

- Monthly to Quarterly: Spectrophotometers

- Annually: Regulatory instruments or as per manufacturer

Related Resources

Frequently Asked Questions (FAQ)

How often should balances be calibrated?

Critical balances should be calibrated daily or before each use. Less sensitive instruments may follow monthly or quarterly schedules.

What’s the difference between mass and weight?

Mass is the amount of matter in an object; weight is the force of gravity acting on that mass. Mass remains constant, weight varies by location.

What is OIML and why does it matter?

OIML is the International Organization of Legal Metrology. It defines global standards for accuracy classes and calibration procedures for measuring instruments.